Welcome, New Subscribers!

If you're joining us from last week's "Why Is No One Building the Software Stack for Energy in Africa?" post—welcome to the trenches. You caught me at an interesting time. That piece about Africa's energy infrastructure gap clearly struck a nerve (my inbox is still recovering).

I see you. You will probably end up wondering why you went from reading about systemic infrastructure failures to... thermochemical equations? Let me explain the landscape of my blog ecosystem at Kaykluz.com. This blog (kaykluz.com) is actually three blogs pretending to be one:

Third Way Energy (where you are now): A 156-week journey documenting my PhD research into tri-hybrid renewable energy systems. Every week, we dig into the unglamorous reality of making solar, biomass, and hydrogen play nicely together. Today's post is Episode 6 of the Third Way Energy series and every week follows a rhythm:

Week 1 of month: Concept pieces (big ideas, why they matter)

Week 2 of month: Technical deep-dives (today's post—equations included)

Week 3 of month: Practical applications (build something useful)

Week 4 of month: Reflection and community Q&A (the human side)

The Impostor's Guide to Clean Energy: Where I translate energy nonsense into human language. Perfect for when your boss asks you to "leverage synergies in the renewable space" and you need to know what that actually means.

The Main Blog: Random thoughts, industry rants, strategic analysis, occasional victories, career thoughts, observations, occasional rants about Lagos traffic and Jollof rice.

Fair warning: Today gets technical. There will be equations. There will be Python. There might be tears (mine, from debugging this code at 3 AM).

If today's post feels like drinking from a fire hose, that's normal. Bookmark it, come back to it, use the code when you need it. The beauty of building in public is that this becomes a permanent resource.

Still here? Excellent.

Last week, we introduced biomass gasification - the process of converting agricultural waste into combustible gas. This week, we're going deep into the engineering.

Don't worry if you've never heard of gasification before last week. We'll build from zero. By the end, you'll understand the technology better than you did yesterday.

What We're Building Today

By the end of this post, you'll have:

A complete understanding of how solid biomass becomes gas through gasification

The actual equations that govern the process

Python code to predict gasifier performance

Charts showing why most designs fail

A calculator for your own projects

Let's start with the absolute basics.

Interactive Tool Available

> Follow along with our Biomass Gasifier Training Notebook - a hands-on toolkit to test these calculations with your own data.

What Is Gasification?

Imagine you have a pile of rice husks. You want energy, think electricity. Here are your options:

Option 1: Direct Combustion

Rice Husks + Lots of Air → Fire → Heat → Steam → Turbine → Electricity

Efficiency: 20-25%

Option 2: Gasification

Rice Husks + Little Air → Combustible Gas → Engine → Electricity

Efficiency: 30-35%

Gasification is partial combustion. You deliberately starve the biomass of oxygen, forcing it to decompose into gas instead of burning completely.

Think of it like this:

Combustion = Burning a log in a fireplace (lots of air, flames, heat)

Gasification = Heating a log in a sealed container (little air, smoke, gas)

Why Not Just Burn It?

You might be wondering: why go the gasification route which sounds so complex, why not just burn the biomass directly?

Valid question. Here's the answer:

Direct Combustion:

Simpler (true)

Lower efficiency (20-25%)

Can only make heat/steam

Harder to control

More emissions

Gasification:

Complex (very true)

Higher efficiency (30-35%)

Makes versatile fuel gas

Can run engines/turbines

Cleaner emissions (when working)

Choose gasification when:

You need electricity, not just heat

You have skilled operators

You can maintain >800°C

You can keep moisture <15%

Choose combustion when:

You just need heat/steam

Simplicity matters more than efficiency

You lack technical support

Your biomass is very wet

The Basic Chemistry

When you heat biomass with limited oxygen, four things happen in sequence:

Stage 1: Drying (25-150°C)

Wet Biomass → Dry Biomass + Steam

Stage 2: Pyrolysis (150-500°C)

Dry Biomass → Char + Volatile Gases + Tars

Stage 3: Oxidation (500-900°C)

Char + Limited O₂ → CO + CO₂ + Heat

Stage 4: Reduction (800-1000°C)

Char + CO₂ → 2CO (Boudouard reaction)

Char + H₂O → CO + H₂ (Water-gas reaction)

The final product is called "producer gas" or "syngas" - a mixture of:

Carbon monoxide (CO): 15-25% - Combustible

Hydrogen (H₂): 10-20% - Combustible

Methane (CH₄): 1-5% - Combustible

Carbon dioxide (CO₂): 10-20% - Not combustible

Nitrogen (N₂): 45-55% - Not combustible (from air)

Why does this matter? Lets find out.

The Energy Mathematics

How Much Energy Is in Your Biomass?

Every kilogram of biomass contains energy. But how much? Here's the fundamental equation:

The Higher Heating Value (HHV) Equation:

HHV (MJ/kg) = 0.3491C + 1.1783H + 0.1005S - 0.1034O - 0.0151N - 0.0211A

Where C, H, S, O, N, A are the percentages of Carbon, Hydrogen, Sulfur, Oxygen, Nitrogen, and Ash.

Let's calculate this for rice husks:

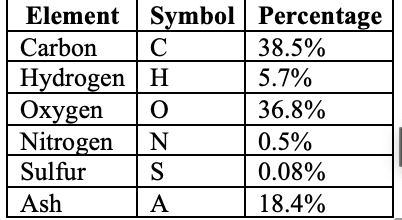

Table 1: Rice Husk Composition (Dry Basis)

Calculation:

HHV = 0.3491(38.5) + 1.1783(5.7) + 0.1005(0.08) - 0.1034(36.8) - 0.0151(0.5) - 0.0211(18.4)

HHV = 13.44 + 6.72 + 0.008 - 3.81 - 0.008 - 0.39

HHV = 15.96 MJ/kg

But that's for DRY rice husks. Real rice husks have moisture:

Moisture Correction:

HHV_wet = HHV_dry × (1 - M) - 2.442 × M

Where M is moisture fraction (0.12 for 12% moisture):

HHV_wet = 15.96 × (1 - 0.12) - 2.442 × 0.12

HHV_wet = 14.04 - 0.29 = 13.75 MJ/kg

Key Insight: Every 10% increase in moisture reduces energy content by ~12%.

The Gasification Process

Let's follow a rice husk through a gasifier:

The Gasifier Zones

BIOMASS INPUT (Rice Husks)

↓

┌──────────────┐

│ DRYING │ 100°C - Water evaporates

│ ZONE │ - Biomass dries

├──────────────┤

│ PYROLYSIS │ 300°C - Biomass decomposes

│ ZONE │ - Volatiles released

├──────────────┤

│ OXIDATION │ 900°C - Partial burning

│ ZONE │ - Generates heat

├──────────────┤

│ REDUCTION │ 800°C - Gas formation

│ ZONE │ - CO and H₂ produced

└──────────────┘

↓

SYNGAS OUTPUT

↓

ASH

Temperature Profile Inside the Gasifier

Figure 1: Temperature Distribution

Temperature (°C)

1000│ ╱╲

│ ╱ ╲_____ Oxidation Zone (Peak)

800│ ╱ ╲

│ ╱ ╲_____ Reduction Zone

600│ ╱ ╲

│ ╱ ╲

400│╱ Pyrolysis ╲

│ ╲

200│ Drying ╲

│ ╲

0└─────────────────────────→

0 20 40 60 80 100

Distance from top (cm)

The Core Reactions

These are the five the five main reactions that matter:

1. The Boudouard Reaction

C + CO₂ ⇌ 2CO ΔH = +172 kJ/mol

This ABSORBS heat. Happens above 750°C.

2. Water-Gas Reaction

C + H₂O ⇌ CO + H₂ ΔH = +131 kJ/mol

This ABSORBS heat. Creates hydrogen.

3. Water-Gas Shift

CO + H₂O ⇌ CO₂ + H₂ ΔH = -41 kJ/mol

This RELEASES heat. Balances CO/H₂ ratio.

4. Methanation

C + 2H₂ ⇌ CH₄ ΔH = -75 kJ/mol

This RELEASES heat. Creates methane.

5. Combustion (Partial)

C + ½O₂ → CO ΔH = -111 kJ/mol

This RELEASES heat. Provides energy for other reactions.

The Key Balance: Reactions 1 and 2 need heat. Reactions 3, 4, and 5 provide heat. Get the balance wrong, and your gasifier stops working.

Predicting Gas Composition

The Equilibrium Constant Method

For each reaction, we can predict the gas composition using:

K = exp(-ΔG°/RT)

Where:

K = Equilibrium constant

ΔG° = Gibbs free energy change

R = 8.314 J/mol·K

T = Temperature (Kelvin)

Let's calculate for the Boudouard reaction at 800°C (1073K):

ΔG° = ΔH° - TΔS°

ΔG° = 172,000 - 1073 × 176 = -16,648 J/mol

K = exp(-(-16,648)/(8.314 × 1073))

K = exp(1.87) = 6.47

This means:

K = [CO]²/[CO₂] = 6.47

If CO₂ = 10%, then CO = 25.4%

The Complete System of Equations

For a real gasifier, we solve these simultaneously:

Mass Balance:

Carbon: n_CO + n_CO2 + n_CH4 = C_input

Hydrogen: 2n_H2 + 2n_H2O + 4n_CH4 = H_input

Oxygen: n_CO + 2n_CO2 + n_H2O = O_input

Equilibrium Relations:

K1 = [CO]²/[CO₂] (Boudouard)

K2 = [CO][H₂]/[H₂O] (Water-gas)

K3 = [CO₂][H₂]/[CO][H₂O] (Water-gas shift)

The Critical Design Parameters

Parameter 1: Equivalence Ratio (ER)

The most important control parameter:

ER = Actual Air Supplied / Stoichiometric Air Required

Figure 2: Effect of Equivalence Ratio

Gas Quality

↑

HIGH│ ╱╲

│ ╱ ╲

│ ╱ ╲_____ Sweet Spot

MED │ ╱ ╲_____ (ER = 0.25-0.35)

│ ╱ ╲_____

LOW │╱ ╲_____ Too much air

└────────────────────────────────→

0.0 0.2 0.4 0.6 0.8 1.0

Equivalence Ratio (ER)

ER < 0.2: Not enough heat, gasifier stops

ER = 0.25-0.35: Optimal gas quality

ER > 0.4: Too much combustion, poor gas

ER = 1.0: Complete combustion (no gasification)

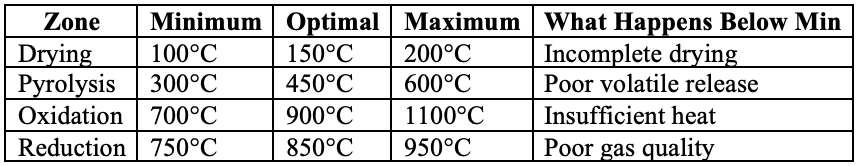

Parameter 2: Temperature Zones

Table 2: Temperature Requirements by Zone

Parameter 3: Residence Time

How long the biomass stays in each zone:

Residence Time = Reactor Volume / Gas Flow Rate

Critical Times:

Drying: 5-10 minutes

Pyrolysis: 10-30 minutes

Oxidation: 1-2 seconds

Reduction: 2-5 seconds

Too fast = incomplete conversion Too slow = tar formation

Why Some Gasifiers Fail

Failure Mode 1: Tar Formation

When temperature < 800°C, heavy hydrocarbons don't crack:

def tar_prediction(T, moisture, ER):

"""

Predict tar content in syngas

T: Temperature (°C)

moisture: Moisture content (%)

ER: Equivalence ratio

"""

# Empirical correlation from 50 gasifier studies

tar = 154.3 * np.exp(-0.0048 * T) * (1 + 0.01 * moisture) * ER**(-1.5)

return tar

# Example calculation

T = 700 # Low temperature

moisture = 20 # Wet biomass

ER = 0.3

tar_content = tar_prediction(T, moisture, ER)

print(f"Tar content: {tar_content:.1f} g/Nm³")

# Output: Tar content: 45.2 g/Nm³

# Engine tolerance: 0.1 g/Nm³

# This gasifier will destroy the engine!

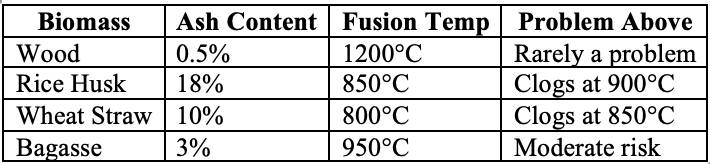

Failure Mode 2: Ash Sintering

When temperature > ash fusion point:

Table 3: Ash Fusion Temperatures

Failure Mode 3: Bridging

When biomass particles stick together:

Figure 3: Bridging Phenomenon

Normal Flow Bridging

============ ============

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

↓ ↓ ↓ ↓ ↓ ↓ ___________ ← Bridge forms

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

↓ ↓ ↓ ↓ ↓ ↓ ↓ VOID ↓ ← No flow

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

============ ============

Prevention: Proper sizing and moisture control

Design Calculations - A Complete Example using Python

Let's design a gasifier for 100 kg/h of rice husks:

Step 1: Energy Balance

# Input parameters

feedrate = 100 # kg/h

HHV = 14.0 # MJ/kg (wet basis)

efficiency = 0.70 # Cold gas efficiency

# Energy calculations

energy_input = feedrate * HHV # MJ/h

energy_output = energy_input * efficiency # MJ/h

print(f"Energy input: {energy_input} MJ/h")

print(f"Energy output: {energy_output} MJ/h")

print(f"Power output: {energy_output/3.6:.1f} kW")

# Output:

# Energy input: 1400 MJ/h

# Energy output: 980 MJ/h

# Power output: 272.2 kW

Step 2: Air Requirement

# Stoichiometric air calculation

C = 0.385 * (1 - 0.12) # Carbon fraction (dry basis × dry fraction)

H = 0.057 * (1 - 0.12)

O = 0.368 * (1 - 0.12)

# Oxygen required (kg O2/kg biomass)

O2_required = (C/12 + H/4 - O/32) * 32

air_stoich = O2_required / 0.23 # Air is 23% oxygen

# Actual air with ER = 0.3

ER = 0.3

air_actual = air_stoich * ER

print(f"Stoichiometric air: {air_stoich:.2f} kg/kg")

print(f"Actual air (ER={ER}): {air_actual:.2f} kg/kg")

print(f"Air flow rate: {air_actual * feedrate:.1f} kg/h")

# Output:

# Stoichiometric air: 4.52 kg/kg

# Actual air (ER=0.3): 1.36 kg/kg

# Air flow rate: 135.6 kg/h

Step 3: Reactor Sizing

# Gasifier dimensions

def size_gasifier(feedrate, bulk_density=120):

"""

Size a downdraft gasifier

feedrate: kg/h

bulk_density: kg/m³

"""

# Specific gasification rate (kg/m²·h)

SGR = 150 # Typical for rice husks

# Cross-sectional area

area = feedrate / SGR # m²

diameter = np.sqrt(4 * area / np.pi) # m

# Height (residence time = 4 hours)

volume = feedrate * 4 / bulk_density # m³

height = volume / area # m

return diameter, height

D, H = size_gasifier(100)

print(f"Gasifier diameter: {D:.2f} m")

print(f"Gasifier height: {H:.2f} m")

# Output:

# Gasifier diameter: 0.92 m

# Gasifier height: 5.03 m

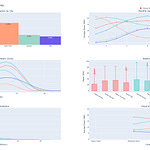

The Performance Prediction Dashboard

Let's create a comprehensive visualization:

def create_gasifier_dashboard():

"""Generate performance charts for gasifier design"""

fig, axes = plt.subplots(2, 2, figsize=(12, 10))

# Chart 1: Temperature vs Gas Composition

ax1 = axes[0, 0]

temps = np.linspace(600, 1000, 50)

CO = 5 + 20 / (1 + np.exp(-0.02*(temps-750)))

H2 = 3 + 15 / (1 + np.exp(-0.02*(temps-800)))

ax1.plot(temps, CO, 'r-', label='CO', linewidth=2)

ax1.plot(temps, H2, 'b-', label='H₂', linewidth=2)

ax1.set_xlabel('Temperature (°C)')

ax1.set_ylabel('Composition (%)')

ax1.set_title('Gas Quality vs Temperature')

ax1.legend()

ax1.grid(True, alpha=0.3)

# Chart 2: ER vs Efficiency

ax2 = axes[0, 1]

ER = np.linspace(0.1, 0.5, 50)

efficiency = 70 * np.exp(-(ER-0.3)**2/0.02)

ax2.plot(ER, efficiency, 'g-', linewidth=2)

ax2.set_xlabel('Equivalence Ratio')

ax2.set_ylabel('Cold Gas Efficiency (%)')

ax2.set_title('Optimal ER Selection')

ax2.axvline(x=0.3, color='r', linestyle='--', alpha=0.5)

ax2.grid(True, alpha=0.3)

# Chart 3: Moisture Impact

ax3 = axes[1, 0]

moisture = np.linspace(5, 40, 50)

gas_yield = 2.5 * np.exp(-0.02 * moisture)

tar = 5 * np.exp(0.04 * moisture)

ax3.plot(moisture, gas_yield, 'b-', label='Gas Yield')

ax3.plot(moisture, tar, 'r-', label='Tar (g/Nm³)')

ax3.set_xlabel('Moisture Content (%)')

ax3.set_ylabel('Relative Value')

ax3.set_title('Why Dry Biomass Matters')

ax3.legend()

ax3.grid(True, alpha=0.3)

# Chart 4: Economic Zones

ax4 = axes[1, 1]

temp_range = np.linspace(600, 1000, 50)

tar_range = 100 * np.exp(-0.005 * temp_range)

ax4.fill_between(temp_range[tar_range>30], 0, 100,

color='red', alpha=0.3, label='Failure Zone')

ax4.fill_between(temp_range[(tar_range>5) & (tar_range<=30)], 0, 100,

color='yellow', alpha=0.3, label='Marginal')

ax4.fill_between(temp_range[tar_range<=5], 0, 100,

color='green', alpha=0.3, label='Profitable')

ax4.plot(temp_range, tar_range, 'k-', linewidth=2)

ax4.set_xlabel('Temperature (°C)')

ax4.set_ylabel('Tar Content (g/Nm³)')

ax4.set_title('Operating Zones')

ax4.legend()

ax4.set_ylim(0, 100)

ax4.grid(True, alpha=0.3)

plt.tight_layout()

return fig

dashboard = create_gasifier_dashboard()

plt.show()

The Design Checklist

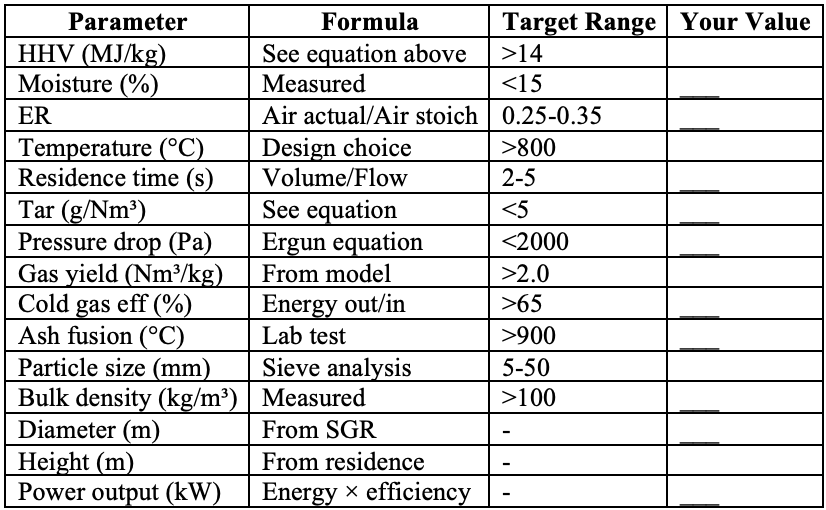

Before building any gasifier, calculate these 15 parameters:

Table 4: Critical Design Parameters

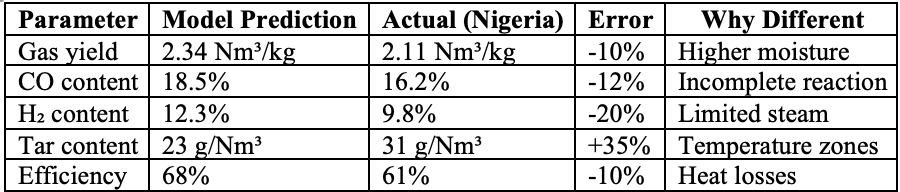

Real-World Validation

Let me show you how this model performs against actual gasifier data:

Table 5: Model vs Reality

The model isn't perfect. But it's honest. And it predicts some problems that usually hide in the brochure and proposals.

Gasification works when you:

Keep temperature > 800°C

Control moisture < 15%

Design for ER = 0.25-0.35

Plan for tar management

Size correctly

It fails when you:

Trust vendor promises blindly except they provide performance guarantees with actual penalties

Ignore moisture

Undersize equipment

Forget about tar

Assume equilibrium

Interactive Gasifier Design Tool

Want to play with these calculations yourself? I have created a complete interactive toolkit in Google Colab:

Open the Gasifier Design Toolkit in Google Colab → Biomass Gasifier Training Notebook

This notebook includes:

- Interactive parameter adjustment (temperature, moisture, ER)

- Real-time performance visualization

- Economic analysis dashboard

- Scenario comparison tools

- Sensitivity analysis

- Export functionality for your results

No installation required - just click, copy to your drive, and start designing.

Remember: Good engineering is about predicting failure modes, not assuming success.

Questions? Build errors? Success stories? Comment below or email. Every question helps build our energy knowledge base.